- Star Atlas CNC Equipment - Professional CNC wire cutting equipment manufacturer

- (+86)15564645864

The cat scratch board wire saw machine is a specialized equipment based on the principle of wire saw cutting, mainly used for irregular cutting of corrugated paper, EVA materials and plastic products, especially suitable for the production needs of customized products such as cat scratch boards. The following is an explanation from three aspects: working principle, core structure, and operating standards

1. Working principle of cat scratching board wire saw machine

The equipment achieves high-precision machining through "CNC design+dynamic cutting", and the specific process is as follows:

- Graphic Design and Parameter Input

By presetting the size, shape, and path of the cutting graphic through computer software, digital instructions are generated and transmitted to the control system. - Material positioning and fixation

The material to be cut is precisely positioned by a pneumatic driven fixing device to avoid deviation or material waste. - Wire saw dynamic cutting

- Wire saw operation: The wire made of hard alloy or high-speed steel rotates at high speed, forming a continuous cutting force

- Trajectory Control: The fixed axis of the material moves along the programmed path, driving the material to contact the wire saw and complete the cutting of irregular contours

- Step by step completion: After cutting, the finished product is automatically transferred to the preset area and enters the next process.

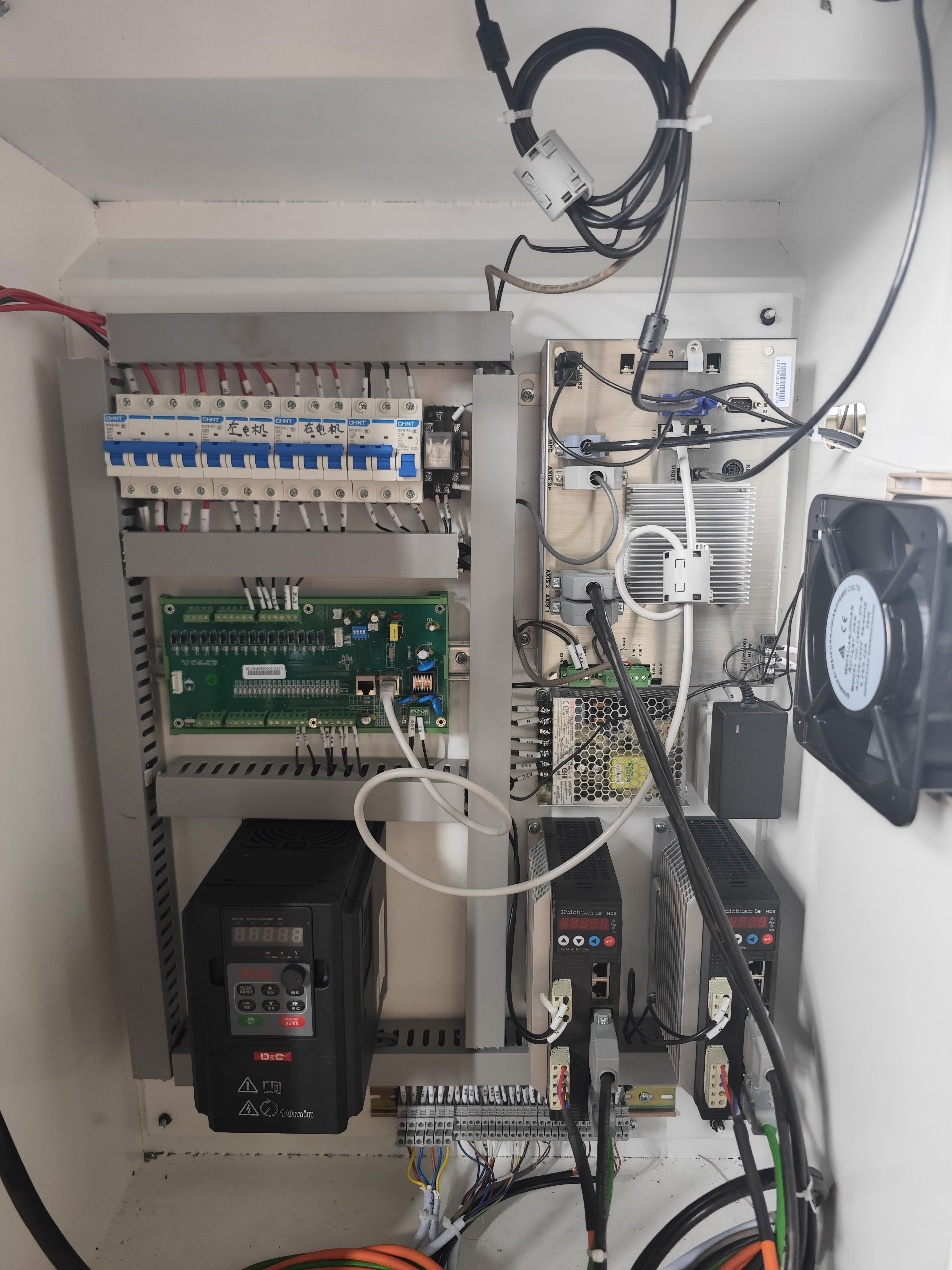

II. Composition of device core structure

The cat scratching board wire saw machine is operated by four modules working together:

Component Function Machine Platform Provide stable support, integrate cutting area and material transfer track to ensure machining accuracy. Numerical Control System Equipped with servo motors and controllers, it performs graphic analysis, path planning, and motion command output to achieve fully automated operations. Wire saw components Using high-strength thread and tension adjustment device to ensure cutting efficiency and edge flatness. Material fixing device Pneumatic driven clamping mechanism enables rapid positioning and dynamic tracking of materials, adapting to complex cutting trajectory requirements.

III. Operating Standards and Maintenance Suggestions

1. Safety operation guidelines

- Wear protective equipment before operation to ensure that the emergency brake button can be activated at any time

- It is forbidden to adjust parameters or touch moving parts during equipment operation

2. Daily maintenance points

- Regular maintenance: Clean the residual debris of the wire saw, check the lubrication status of the transmission components, and prevent wear and tear

- Precision Calibration: Verify the synchronization between the CNC system and the mechanical structure on a monthly basis to avoid cutting deviations.

3. Pre production testing process

- After starting up, conduct a no-load trial run to confirm the tension, air pressure stability, and system response speed of the wire saw

- When abnormal noise or data is detected, immediately stop the machine for maintenance, and only after troubleshooting can it be put into operation

IV. Technical Advantages and Application Prospects

The cat scratching board wire saw machine, with its characteristics of numerical control and high flexibility, significantly improves the processing efficiency and consistency of irregular products, especially suitable for small batch and multi variety order needs. In the future, by integrating AI visual inspection and adaptive algorithms, the equipment is expected to further optimize cutting accuracy and material utilization, promoting the upgrading of pet supplies, packaging, and light industry manufacturing towards intelligence

Star Atlas

Professional wire cutting equipment, just choose Star Atlas CNC, one-to-one professional service, contact us

Related Posts

- Cat scratch board equipment, cat scratch board machine, CNC wire saw machine

- Honeycomb cardboard shaped cat scratch board cutting machine CNC wire saw machine

- High speed irregular corrugated paper cat scratching board cutting equipment

- Cat scratch board irregular cutting equipment dual workbench CNC wire saw machine

- Reasons for choosing Star Atlas CNC wire cutting machine

Popular Posts

© 2025. All Rights Reserved.